Robot DIY Pkg

ROBOTIC MOSAIC ASSEMBLY IS THE FUTURE OF MOSAIC INDUSTRY!

Mosaic Robot series are developed by ezmosaic.com

A typical mosaic projects for floor, plaza and pool may have more than 100,000 tiles.

I’ve done one with 1,200,000 tiles. It is extremely time consuming to assemble mosaic tiles.

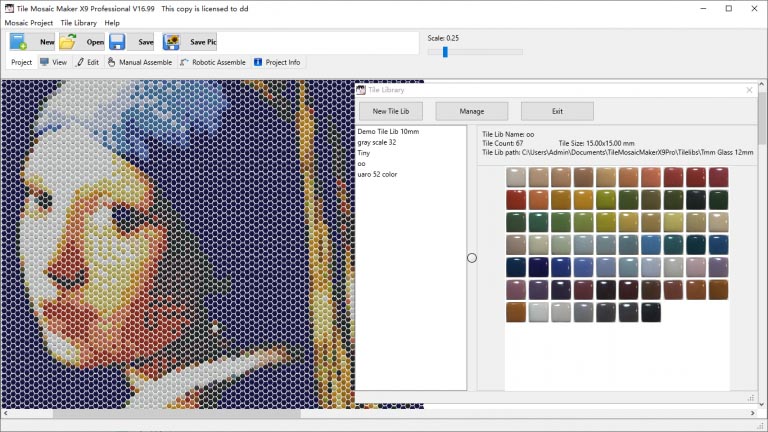

It is really difficult to deal with small size tiles, such as 8x8mm, 10x10mm, 15x15mm, or similar size.

A skilled labor can finish no more than 10,000 mini tiles per day. That is why we started research and develop the automatic mosaic mounting system.

The common features and workflow of a robot powered mosaic workshop

There are many types of mosaic workshop exist. They share some common features and use similar workflows.

Features

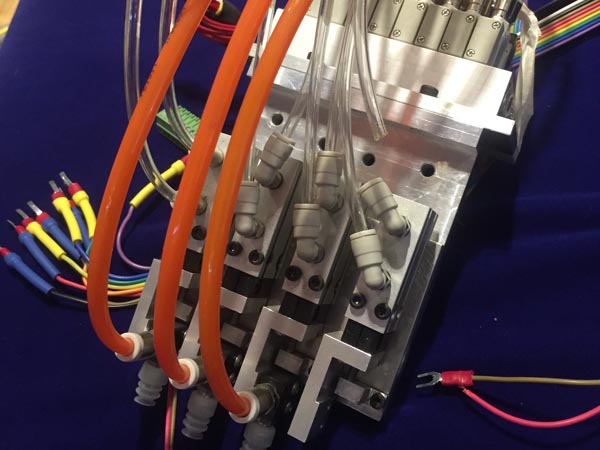

Tile storage.

Feeding system.

Pick and mount robot.

Receiving system.

Finalizing workspace

A Typical Workflow

A. Tile preparation. Worker put a bag of tiles to Disc Feeder, use them to fill Tile Slots.

Filled Tile Slots will be stored on the Tile Slot Storage. Each slot can hold around 240 tiles(8mm).

For each color I suggest you to prepare 20 or more slots in the storage.

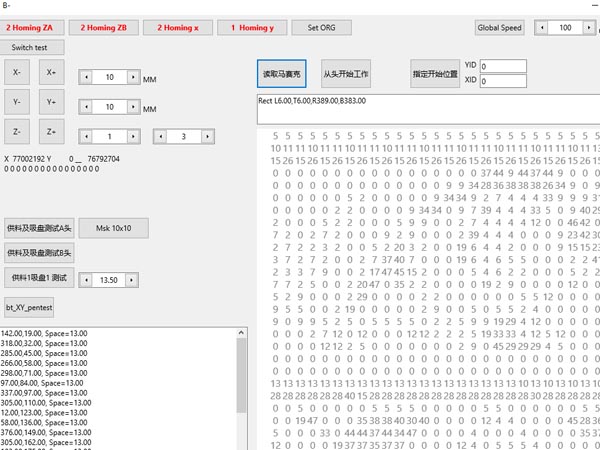

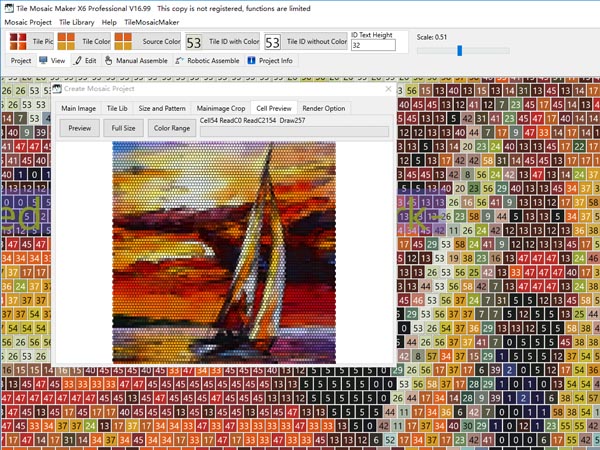

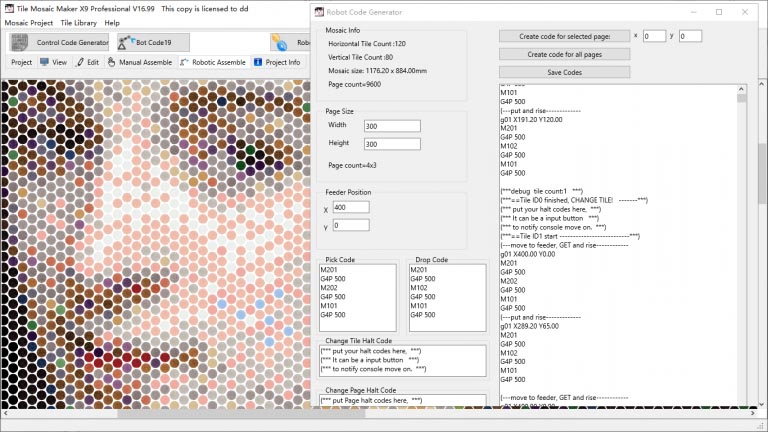

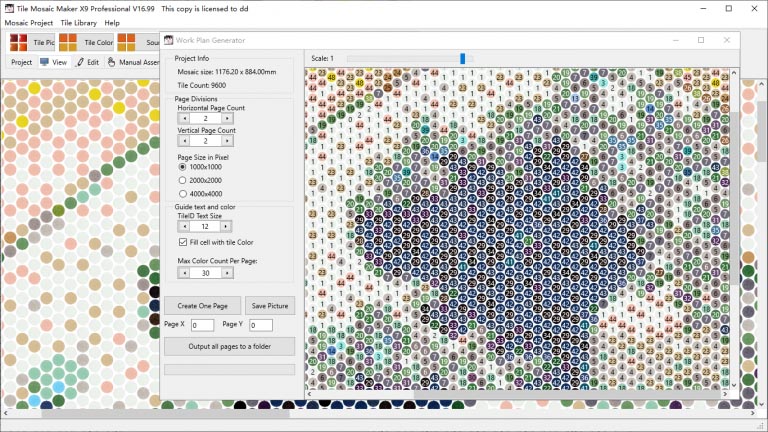

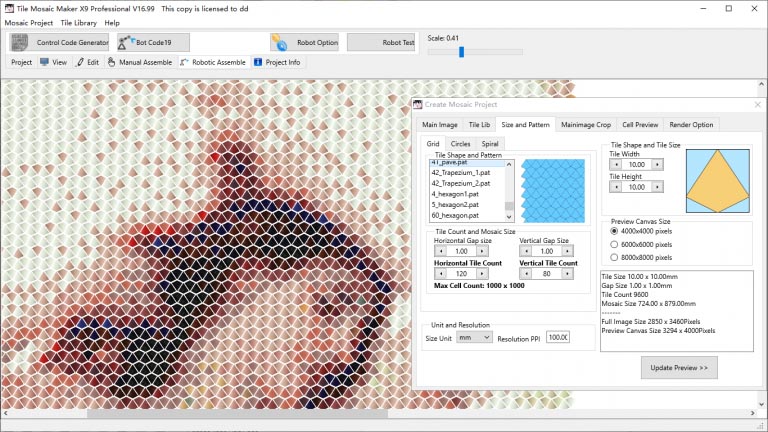

B. Design a mosaic.

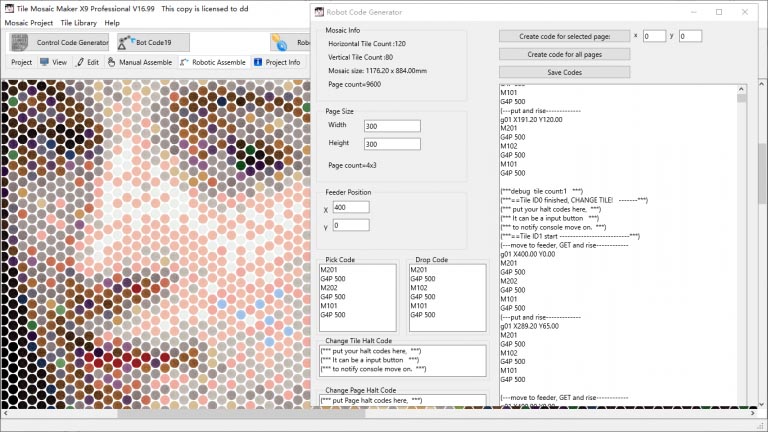

C. Load the mosaic file to Robot Console.

D. Worker get Tiles Slots from the storage, mount them to the feeder area of the robot.

E. Worker get Empty Pallets from Empty Pallet Storage , and mount them to pallet area of the robot.

F. Run Mosaic Assemble Robot.

G.Once a Mosaic Pallet is filled, you will get a mosaic ready prompt. Worker will remove it from the robot, mount a empty pallet, and hit ‘Continue’ button.

H.Worker will do finalizing process on worktable.

Demo video, Three types of our mosaic robot.

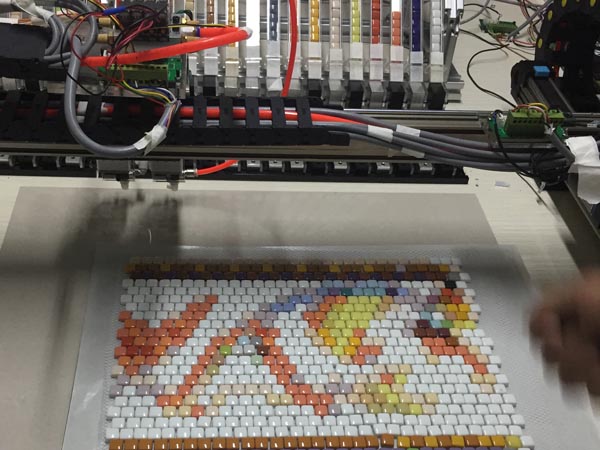

Cartesian Robot, the most popular model.

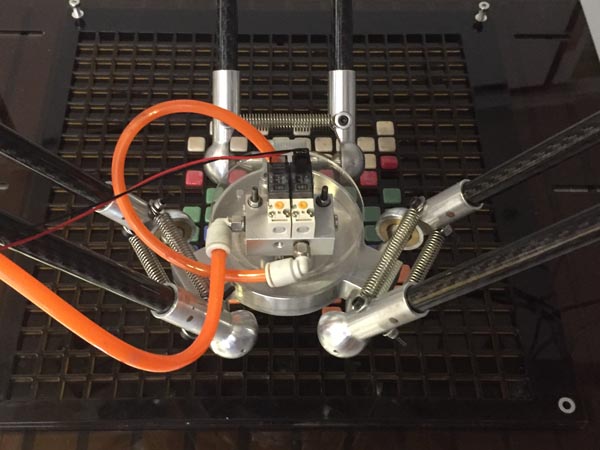

Delta Robot, this type is fast for tiny tiles.

Delta Robot with 4th rotate axis. it is designed for mosaic patterns need to rotate tiles.

| Cartesian Robot | Delta Robot | Rotate Test |

|---|

Demo Video, Feature Experiments

Speed test with 10mm tiny tiles

| Speed with tiny tile | Glue jet | Combo test, glue and tile. |

|---|

Q&A

Q: What kind of robot structure will be used?

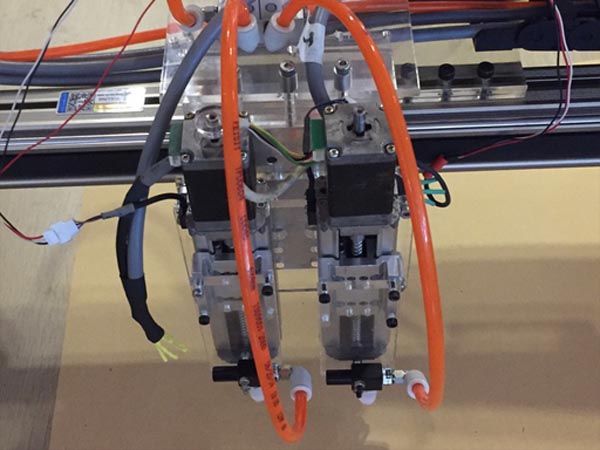

A: Cartesian Robot is a common structure of industry robot.

The main body is 'H' structure, include 2 X axis modules and 1 Y axis.module.

There are 2 or more Z axis module mounted as 'The Picker Axis'.

Each Z module equipped a vacuum picker.

Q: Why do we use several Z axis modules?

A: Time saving.

Q: Motor module vs Air cylinder?

A: Motor provide smoother movement, Air cylinder is cheaper but may cause impact.

Robot Type Comparison

| Type | Tile Size | Max Color Count | Work Area | Speed | Cost | Unique Feature |

|---|---|---|---|---|---|---|

| CARTESIAN Lite | 5x5mm to 15x15mm | 32 colors | 300x300mm x2 | 1200 to 2400 tiles/hour | $4000 to $8000 | Low Cost |

| CARTESIAN Pro | 5x5mm to 40x40mm | 100 colors | 300x300mm to 1000x1000mm | 3000 to 6000 tiles/hour | $6000 to $15000 | Best for regular patterns |

| *DELTA | 5x5mm to 40x40mm | 60 colors | 300x300mm to 800x800mm | 3000 tiles/hour | $8000 to $20000 | can process rotate patterns |

*We do not offer Delta Robot at this moment, It need more testing in our lab and workshop.

Feeder Type Comparison

| Type | Capacity | size | Control/Develop | Speed | Cost |

|---|---|---|---|---|---|

| Gravity Slot | <200 tile | Slim and long | Easy, might jamming | Normal | |

| Gravity + Vibriation Slot | <200 tile | Slim and long | Easy, anti jamming | Very Fast | |

| Vibriation Disc | 1000 to 5000 tiles | Large | anti jamming | Very Fast |